1955 John Deere 40 Utility

Questions - Answers provided by YOU!

April 14, 1999 - I don't have a serial tag. I know that on the Dubuque tractors, the engine blocks were stamped with a number on the right front of the block, and that records were kept as to which serial numbers went with which blocks. However, to get all this information, you have to go through your Deere regional manager. The block number on my 40U is 108931.

I don't need an exact serial number, but I would like to try to get a rough idea of where the serial number would be. So, if you have a 40 of any style, would you please e-mail me your block number, your serial number, and your tractor style (U, T, W, S, etc.)? (Name and address is not required.) I believe this information could probably lead to a general conclusion as to what serial number (or range) my tractor falls in. (If you can't find your block number, this page should help you locate it.) If I get enough response, I will post this information on another page to help others. In the meantime, here is some more information that may help you find the age of your 40 Utility. (Updated June 8, 1999)

| June 8, 1999

A friend of mine who buys and sells tractors received a 40U today, so I went over and took a look. This was a very nice 40U, serial number 63986, block number 106556. My friend bought this out of Ontario, Canada. It was apparently built for export, as the decals on it include "Made in U.S.A.", and this was under the other decals that had been placed on it. This tractor was very straight, everything appeared to be generally correct. It had the lights and light brackets, the correct ignition/light switch, etc. The top-link was an after-market one. It ran pretty well, though it smoked just a little and the carb probably needs a rebuild. But overall it was a nice little tractor. Here is an interesting note: Both this tractor and my utility did not have long, angled shift levers like the parts book shows. Instead, the shift lever appeared to have been cut in thirds, the middle third thrown away, and the two ends welded together, resulting in a short, straight shift lever. On this tractor, the lever was short enough to work okay. On mine, the lever was just long enough to cause you to pinch your fingers between the steering wheel and the shift lever when in 1st gear, so I replaced it with the proper one. QUESTION: Has anyone else seen this, or seen some sort of pattern like this? Could this be something commonly done in Canada, as both tractors came out of Canada? If you have any ideas regarding this, let me know and I'll share them on this site. ANSWERS: QJ writes, "My shift lever is short and straight. It appears to be stock, but every pic I've seen including the breakdown at my dealer, shows the long angled lever. I don't know if I should replace it or leave it alone. I'm a firm believer in it ain't broke, don't fix it, but I want it to be all original. We'll just have to see." ANSWER provided in Nov-Dec 1999 issue of Two-Cylinder, page 12: Service Considerations - Overshifting - Prior to serial numbers 75146 for the Tricycle, 68869 (Standard), 66000 (Crawler), and 62698 (Utility), transmission shift levers had a spherical-shaped bottom end. These levers are easy to identify without removal to check the bottom end, as they had an integral knob (for gripping when shifting). These early-style levers allowed overshifting, a condition whereby movement of the shift lever caused a transmission sliding gear to travel past the neutral position and become engaged in gear while the shift lever was still in neutral. When this occurred, the operator could not shift the transmission until the shift lever or transmission cover was removed and the sliding gear was returned to neutral. To prevent overshifting, the bottom end of the later shift-lever was changed to a barrel-shaped design which maintained the necessary alignment of slots in the shifter forks. The new-style levers can be identified by their being straight (on wheel tractors) rather than bent, and the use of a removable shift knob like that used on Touch-o-matic hydraulic control levers. The crawler lever retained its bent shape to avoid interference with the operation of steering clutch levers, but it did get the new knob. QUESTION: Are the shift levers on the 40's generally "sloppy"? Are there any good tips for tightening them up? |

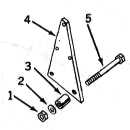

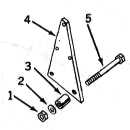

| The parts book shows that the correct fender attaching hardware for a Utility is a flat plat with spacers between the plate and the rear housings. In fact, tonight I looked at 40U SN 63986 BN 106556 and it matches the parts book. It should look something like this. ==> |  |

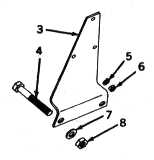

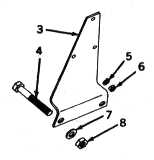

| However, my tractor (40U BN 108931) has the Two-Row Utility fender attaching hardware, consisting of one angled bracket and no spacer. It still fits the correct 40U fenders. It looks like this. ==> |  |

QUESTION: Does anyone know if maybe John Deere decided to only use the one fender bracket for both styles? If so, at what serial number did this change occur? Or were the brackets on my tractor simply replaced at one time with the other style bracket? Any information you could send me would be appreciated.

The 40 Utility has two PTO's available. One is a conventional PTO running from the transmission power shaft at 540 RPM. The other is called an auxilliary PTO, running from the transmission input shaft at engine speed at around 1800 RPM, for use in high-speed applications such as pumps. The 40 Parts Catalog shows not parts that connect to the auxilliary PTO. Also, it appears that there is some sort of clearance problem with the auxilliary PTO and the anchor yoke assembly.

QUESTIONS: Has anyone ever seen the auxilliary PTO in use? Where can equipment (or at least information about equipment) be obtained? What about the clearance issue?

ANSWER: I discussed this with J. R. Hobbs at a tractor show on August 28, 1999. He indicated that Deere never made any equipment to use this PTO, but other suppliers did. Deere would work with the suppliers to provide the equipment. Also, where most applications for this PTO were required, a 3-point hitch was not, and the 40 Utility could be ordered with the 3-point deleted. Therefore the clearance was not an issue.

If you have any specific John Deere 40 questions you would like asked, let me know and I'll add them to this page.