|

|

| 60001-62733 | 62734- |

John Deere 40 Design Changes, Tips, and Hints

Design Changes to the 40U (and other 40's)

Drawbar

Assembly

Grill Assembly

Steering

Wheel

Steering Gear

Fender

Brackets

40 S Lift Arms and

Springs

Miscellaneous Tips and Tecniques

Stockorder Plan to

save money! $$$ :-)

Paint Colors

Sudden engine jam

(worked fine before)

Take the Parts Catalog

along

Replacement lower sealing

plate (M 88 T)

Loosen a tight choke

rod

Cooling system

problems?

Here is some further information on 40 Utility Tractors, some of which relates to the other 40's as well. (Click on the diagrams to view full size.)

I have noticed, by reviewing the parts books, that there were at least two significant changes to the 40U during its run. I have no idea why these changes were made, but would welcome any substantiated information.

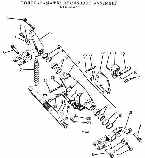

Drawbar Assembly - The first change involved the drawbar assembly. The earlier model from 60001 thru 62733 used the hitch style on the left. All those from 62734 up used the assembly on the right.

I'm guessing that the change was made to make the drawbar assembly stronger. I received a note from someone with the early style drawbar who was reversing the rear housings because the holes where the drawbar assembly attached were cracked. If you study the diagrams, you can see that in the early design, all the weight and leverage of the drawbar was transferred to the close bolt holes in the rear housings. After the design change, the drawbar attached in front of the transmission, removing the twisting leverage on the rear housings. I'd be glad to hear from anyone who knows more about this than I do.

Grill Assembly - The second change involved the grill. The grill was modified from a single screen to a split screen. The change occurred as noted in the caption. J.C. of Columbus, OH passed along the following thought, "The early U's and C's had a one piece grill, then went to a two piece to match the S and T and W grill. My OPINION is that the change was made to eliminate having different parts across the tractor line - although a 40T front hood won't fit on a 40 U." I also read recently that the T's originally had the split hood because certain tillage equipment had to be mounted someplace "front and center". So it would make sense that the T couldn't change, and the others were modified to match the look of the T.

|

|

| Crawler (60001- ) Standard (60001-69403) Utility (60001-63119) |

Hi-Crop, Tricycle, Special, and Two-row utility (60001- ) Standard (69404- ) Utility (63120- ) |

On my 40U, both of these modifications have taken place. Therefore I know my tractor serial number is higher than 63119. Even if you are not interested in finding the exact serial number of your tractor, sometimes you need to have an idea where it falls in order to get the correct parts. Using methods like these can help you narrow that range down.

Steering Wheel - J.C. noted a couple of other things as well. The first is that there was a steering wheel change. He writes, "The steering wheel was made larger to make it easier to steer. I have a loader on my 40S, and when it's loaded, it's really hard to steer." The parts catalog does not show different pictures for the two wheels, but they do list different part numbers with a serial number break as follows:

|

Early Style Steering Wheel |

Late Style Steering Wheel |

| Standard ( -69403) Tricycle ( -75948) Utility ( -63119) |

Standard (69404- ) Tricycle (75949- ) Utility (63120- ) Hi-Crop, Special, and Two-row utility (60001- ) |

It appears, based on my chart that this would have been applied at about the same point in time for all styles. Here are a couple of other questions about the steering wheels:

1. Are the steering wheel centers identical (i.e., are the steering wheels interchangable)?

2. What were the diameters of the two styles?

Any ideas and suggestions are welcomed!

Steering Gear - The other item that J.C. noted was a major change in the steering gear. "The steering sector was changed so that the sector has two pins following the worm instead of the one. This is to provide more wearing surface - i.e., not to wear out so fast. We had a new 40U that we mowed roadsides with every summer for six years, and we wore out the steering system a couple of times." Here are the three different types of steering gear assemblies:

| Fender Brackets

Here is another piece of information. The parts book shows that the correct fender attaching hardware for a Utility is a flat plat with spacers between the plate and the rear housings. In fact, tonight I looked at 40U SN 63986 BN 106556 and it matches the parts book. It should look something like this. ==> |

|

|

However, my tractor (40U BN 108931) has the Two-Row Utility fender attaching hardware (or maybe the 420 U bracket) , consisting of one angled bracket and no spacer. It still fits the correct 40U fenders. It looks like this. ==> |

|

Does anyone know if maybe John Deere decided to only use the one fender bracket for both styles? If so, at what serial number did this change occur? Or were the brackets on my tractor simply replaced at one time with the other style bracket? Any information you could send me would be appreciated.

Lift Arm and Return Springs - I have seen some

questions on whether the 40 S had two lift arm return springs or only

one. The current parts catalog shows only one return spring (on the

left side), and the right lift arm is part # M1840T. Here is the

picture from the Parts Catalog.

Lift Arm and Return Springs - I have seen some

questions on whether the 40 S had two lift arm return springs or only

one. The current parts catalog shows only one return spring (on the

left side), and the right lift arm is part # M1840T. Here is the

picture from the Parts Catalog.

I own a document (May 1953 Service Bulletin) that would indicate that, while the 40 S was originally designed with two return springs, only one was used in production. However, some of the early documentation (owner's manual, parts catalog) was already printed and shows two return springs. It would also appear that, while the spring was not used, no other parts were changed. Therefore, a second spring could still be attached if desired. However, the addition of a second spring will reduce the load capacity of the lift because the spring itself will add load.

I have heard from some who have both springs, from some who have the

mounting holes but no second spring, and from some who have no mounting

holes for the second spring. It would be my guess that at some time, to

reduce manufacturing costs, Deere probably removed the mounting holes.

As the spring was never required in the first place, removal of the

holes would not count as an engineering change (change to form, fit, or

function) and would therefore not be noted in the parts catalogs.

Other Hints and Tips

JCN from Columbus, OH passed along the following tips:

I discovered that my dealer has a "stock order" plan. If you call items in before Thursday, they will come from the regional warehouse with next week's shipment on the following Thursday, and the dealer will give me a 10% discount because these parts do not have to go into their inventory process. Helps me on the pricey items.

Getting the correct color of paint for the right part of the [model 40] tractor is something I've not found all in one place.

Use Pre-1964 yellow for Industrial Yellow

Use Classic Green for Green

Use Blitz Black for lights, seat frames, and black dashes

Today's yellow is the same as the old yellow.

Use silver (unspecified brightness) for spin-out rims.

Everything is green unless otherwise specified.

Jorde decals have the best reputation.

John Deere parts kits for decals are not necessarily "correct".

(The following is a paraphrase from information sent by JCN.) If the engine on your 40/320/420 suddenly jams, and there is plenty of oil and none of the other usual "engine seizing" symptoms, your started pinion may have jammed into the flywheel ring gear. My clue was that there was NO noise when the starter switch was closed. Took the starter off and the engine was free.

These tractors are notorious for the starter locking. That is one of the reasons you can never find one with the battery box sheet metal. People working on these tractors took them off because it was time consuming taking them loose every time the starter locked. Just loosen the starter, back it out, and reinstall it. It will happen again.

Another possibility is a sticky pinion gear shaft. I looked at the starter on my 40U - which jammed the day of the sale when I bought it. The shaft on which the pinion gear runs was very gummy - almost sticky. A couple shots of WD-40 really made a difference. I can see how a low battery which would not spin the engine fast enough to start it could get stuck on a compression stoke, and a gummy starter would not disengage. Next time you have the toolbox off, pull the starter and oil the shaft.

Take your parts manual to any tractor function where you might buy parts! This way you can verify you are buying the correct items!

Part M88T (lower sealing plate) is a part that sometimes

sticks to the bottom of the oil filter. This is not a problem when the

filter is in use. But if not noticed when the filter is changed, it may

accidently get thrown out. JCN sent along the dimensions required for

making your own plate. I have drawn these in CAD and turned it into an

Adobe Acrobat document.

![]() Get your copy of the plans

for M88T here.

Get your copy of the plans

for M88T here.

![]() Get the

free Adobe Acrobat Reader for PDF files

Get the

free Adobe Acrobat Reader for PDF files

Stiff choke rod? JCN passes along this suggestion: Loosen the set screw on the choke rod at the carb choke fitting (If the screw head is up, a long shanked screwdriver will get to it - if the head is down, you'll need to remove the gas line, carb bolts, throttle rod, and twist the carb away from the block to get to the screw head). Pull the choke rod completely out of the outer housing - and lubricate it. i prefer plumbers grease; waterproof, not runny. Push the choke rod back into the cable housing, and reattach at the carb. Voila - a smooth, easy acting choke for the next 10 years.

Having problems with your cooling system? Check this page to get some ideas of what to look for.

Thanks for passing these along!

If you come across any other interesting and useful tidbits that would be helpful to share with others, let me know!